OUR PRODUCTS

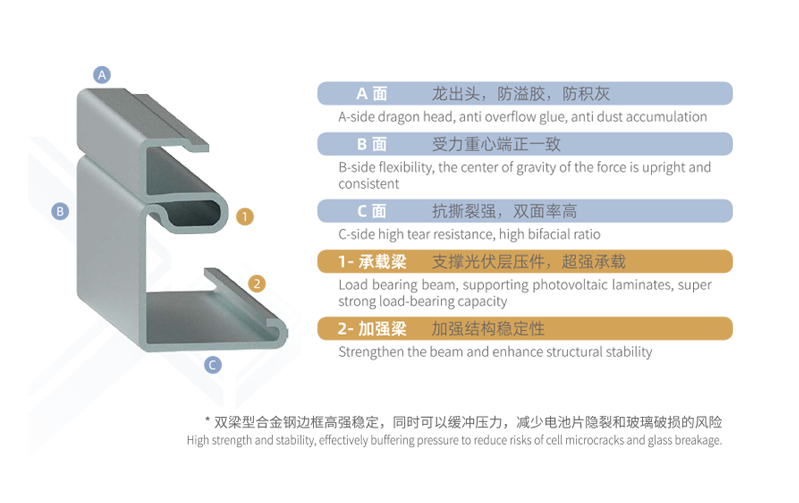

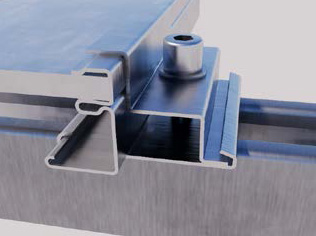

DOUBLE-BEAM ALLOY STEEL FRAME

Steel-Flex Synergy With a unique structure, the frame combines steel's strength with its elastic properties, improving module load capacity and enhancing system safety.

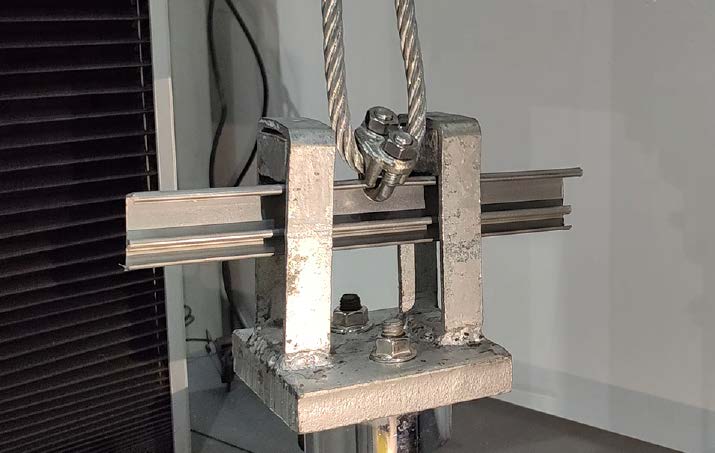

Super safe -Steel double toothed bite angle code

- Precision assembly, no need to modify production equipment.

- Explosion-proof, no glass breakage risk during framing.

- Anti-frame detachment, corner pull-out force >800N

- Prevents galvanic corrosion, same material for corner pieces and frame.

High Compatibility

Easy Assembly: Framing method is consistent with aluminum, enabling smooth transition between steel and aluminum.

Mixed Use in Power Stations: Mounting with clamps and bolts is identical to aluminum frames, supporting mixed installations.

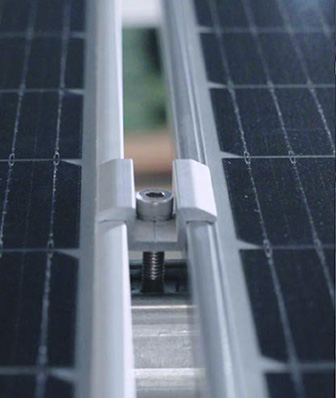

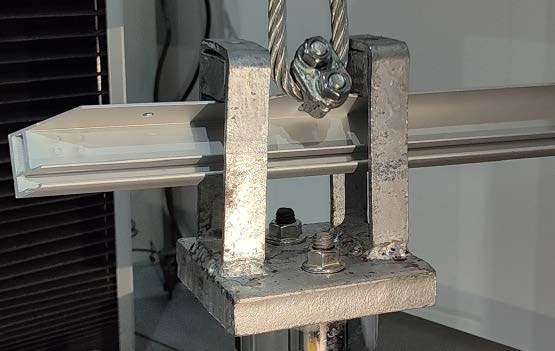

Ultra-Safe Accessories for Power Station Installation

For standard installation, the double-beam alloy steel frame is fully compatible with aluminum frame accessories. For enhanced safety requirements, ultrasafe accessories are also available.

- Steel Clamp: Dual lock hook-and-press structure prevents loosening or falling off, ensuring secure installation of large modules.

- Locking Washer: Increases connection strength, prevents bolt rotation and loosening, improves efficiency, reduces O&M costs, and enhances system safety.

* With the enlargement of components, the pressure on component mounting holes has increased by more than twice.

* With the enlargement of components, the pressure on component mounting holes has increased by more than twice.

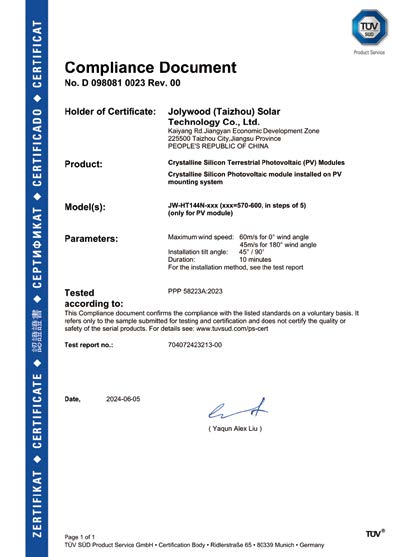

Exceptional Wind Load Resistance

Double-beam alloy steel frames passed wind tunnel tests at Central South University: 60 m/s on front side—resists typhoon level 17; 45 m/s on rear side—resists typhoon level 14.

Case

On March 24, 2024: grid-connected in Huiwen Town, Wenchang City, Hainan.

Latitude and Longitude of Huiwen Town: 19.466915° N, 110.736343° E

Exceptional Snow Load Resistance

Using top-grade materials and strong dual-beam structure, the frame withstands loads up to 10,000Pa, supporting snow thickness up to 4.6 meters.

-

* Double-beam alloy steel frame modules demonstrate an 85% higher front-side load capacity and a 75% higher back side load capacity compared to aluminum frames under the same conditions.

-

210-132 version component ultimate load test, sandbag weight 3.03 tons

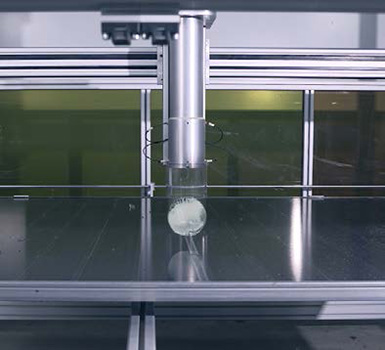

Exceptional Hail Impact Resistance

The frame's elasticity absorbs part of the hail's impact, reducing risks of glass breakage and cell microcracks, enhancing station safety.

* Hail Impact Test

Super tear resistance

With high-strength alloy steel and reinforced C-side beam design, tear resistance reaches 6200N-over three times that of aluminum-effectively resisting level 17 typhoon impacts.

2.5 mm aluminum frame: 1863N

2.5 mm aluminum frame: 1863N 1.0 mm double-beam alloy steel frame: 6200N

1.0 mm double-beam alloy steel frame: 6200NHigh Corrosion Resistance — Same Service Life as PV Racks

Using the same Zn-Al-Mg coated steel as PV racks, with excellent weather resistance and self-healing properties, ensures over 30 years of service life.

- In standard environments, the coating offers sufficient corrosion protection.

- In harsh environments, a specialized coating enhances resistance even further.

- Outdoor exposure in Tongsheng City: corrosion rate of 15-25g/ ㎡ for 8 years at a distance of 100KM from the seaside

- Outdoor exposure in Nakashiro Village, Okinawa Prefecture: 8-year corrosion rate of 35-45g/ ㎡ at a distance of 30M from the seaside

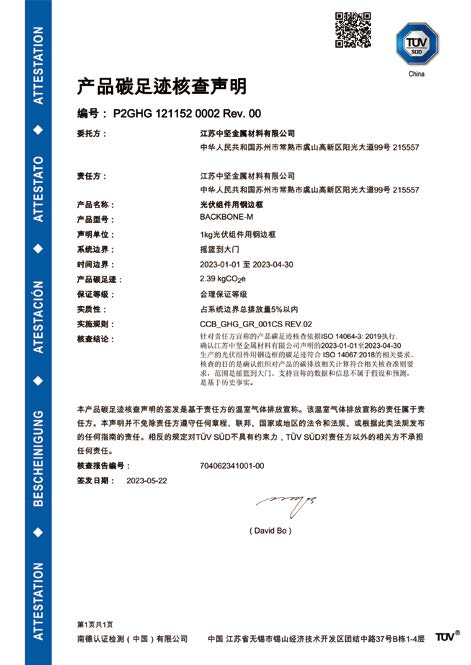

Ultra Low Carbon — Helping PV Modules Cut Emissions

Through steel smelting, frame forming, and glass thinning, the double-beam alloy steel frame reduces carbon emissions by up to 61.8%, lowering emissions by 73,700 tons per 1GW of modules.

Carbon Reduction in Frame Forming Process

The physical roll forming process of Double-beam alloy steel frame has 99% less carbon emissions than the hot extrusion process of aluminum alloy frame, 1GW photovoltaic modules reduce carbon emissions by 27800 tons.

Carbon Reduction in Frame Materials

The carbon emissions of double-beam alloy steel frame are 83% lower than those of the aluminum frame material, 1 GW photovoltaic modules reduce carbon emissions by 32200 tons.

Carbon Reduction in Glass Thinning

Double-beam alloy steel frame helps reduce carbon emissions in glass by 30%, and 1GW photovoltaic modules reduce carbon emissions by more than 13600 tons.

Application Field

BACKBONE Material devote ourselves to provide innovative products and excellent service for the global PV power plant and PV module manufacturing company.

Whether in extremely cold or hot areas, whether in plains or plateaus, BACKBONE steel frames will be able to provide energy to PV power plants. BACKBONE steel frames make the PV module thinner and lower in cost, make the operation of PV power plants safer and more profitable.

-

Ningxia Xinghai New Energy 1,000 MW Photovoltaic Desert Control Composite Project

-

Ningxia Xinghai New Energy 1,000 MW Photovoltaic Desert Control Composite Project

-

Huaneng Zhonglai Qinshui 120 MW Photovoltaic Project

-

Huaneng Zhonglai Qinshui 120 MW Photovoltaic Project

-

Rooftop Solar Photovoltaic Comprehensive Development Project of the Party School of Jiaxing Municipal Committee of the CPC

-

Huiwen Town, Wenchang City, Hainan Province Photovoltaic Module Project

-

Household Photovoltaic Module Project of Dong Village Committee, Xiyan Town, Yuxian County

-

Yili Chemical Dual-Beam Steel Frame Photovoltaic Module Project

-

Nagqu, Tibet Dual-Beam Steel Frame Photovoltaic Module Project

-

Jiaxing Tongxiang Household Photovoltaic Module Project

-

Vietnam Kindergarten Photovoltaic Module Project

-

Bavaria, Germany Photovoltaic Module Project